Assembly

Assembly With TWP

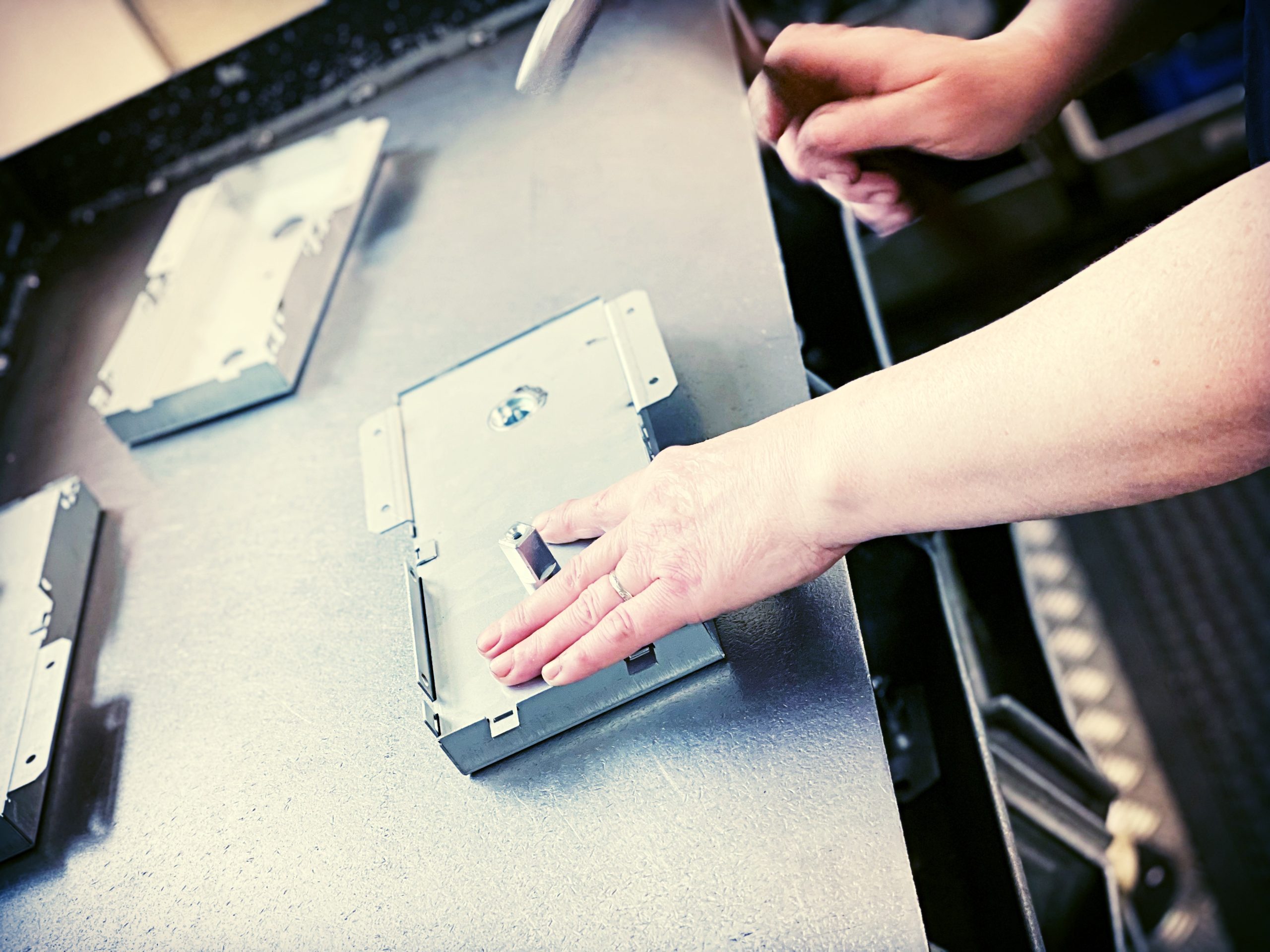

In the manufacturing sector, assembly refers to the process of combining individual components or sub-components to create a finished unit or product. For a pressings company like TWP Manufacturing, assembly involves the fabrication and integration of various sub-components according to a bill of materials (BOM) to produce a complete and functional final product.

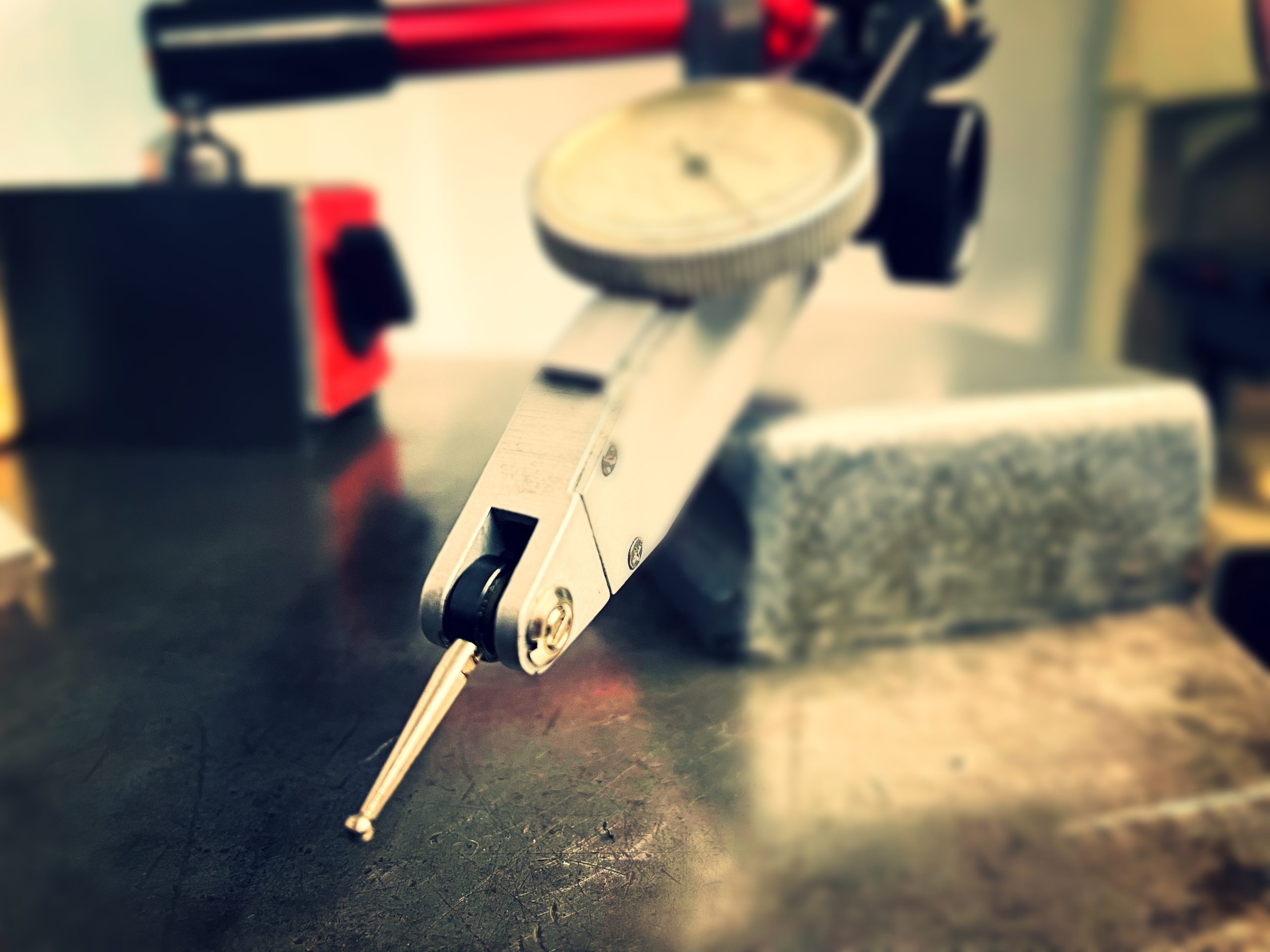

ISO 9001:2015

ISO 9001:2015 is a globally recognised standard for quality management systems (QMS) for a variety of organisations.

Assembly

From concept to finished item, we are able to manufacture and most importantly assemble your finished product for you, even including packaging - ready for you to sell.

Knowledge

With fully trained staff, and clear and concise work instructions, our team follow rigorous standard operating procedures to ensure top quality assembly is adhered to.

Experience

We are very proud to have a high success rate in the retainment of our workforce. This ensures that our team know your products, ensuring uniformity during the assembly operations.

Manufacturing Assembly & BOMs

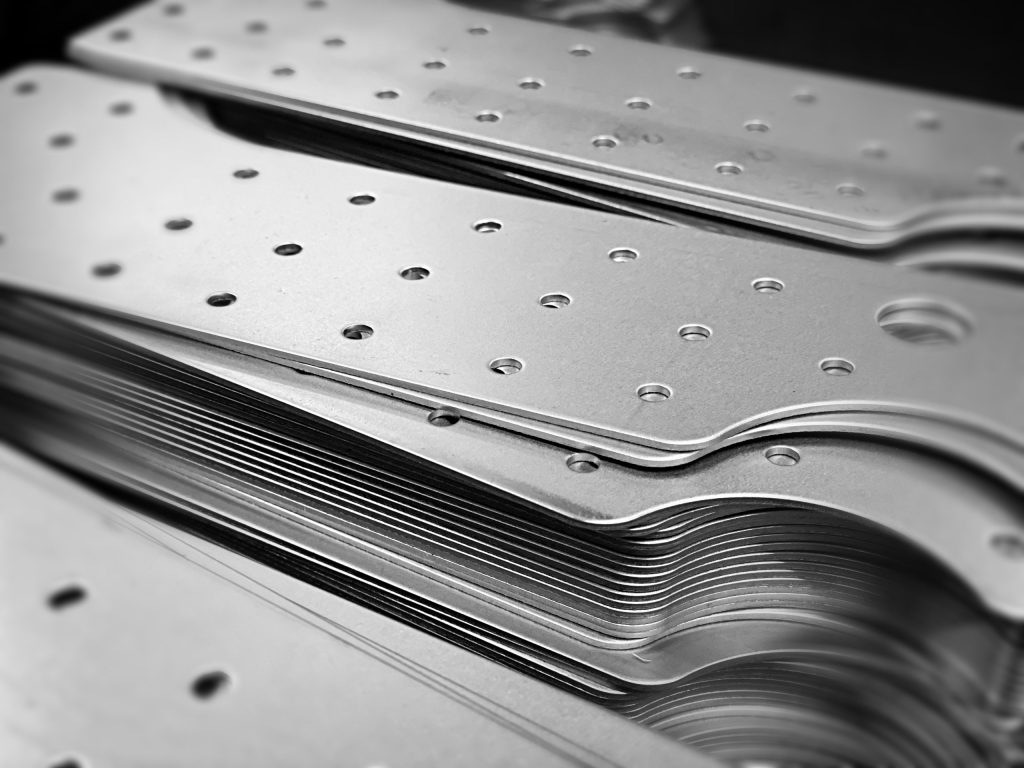

BOM Analysis: The assembly process begins with a thorough analysis of the BOM, which specifies the list of required components and their quantities. The BOM provides a detailed breakdown of the parts needed to create the final product.

Component Manufacturing: We design and manufacture the majority of sub-components in-house. This involves utilising presses, stamping machines, or other specialised equipment to produce the required metal parts. These sub-components are manufactured based on precise specifications and quality standards.

Procurement of Components: For components that are not manufactured in-house, TWP procures them from external suppliers. This involves sourcing the required parts based on quality, cost, lead times, and other factors.

Assembly

Sub-Assembly: Once all the necessary components are available, the assembly process begins. Sub-assembly refers to the construction of smaller modules or sub-units that will eventually be integrated to form the complete product. This step may involve specialised jigs, fixtures, or tools to ensure accurate and consistent assembly.

Final Assembly: In the final assembly stage, all the sub-components and sub-assemblies are combined to create the finished product according to the BOM. This involves precision fitting, alignment, and securing of parts using techniques such as welding, fastening, or adhesives.

Quality Control: Throughout the assembly process, rigorous quality control measures are implemented to ensure that each step meets the required standards. This includes inspections, testing, and verification of dimensions, tolerances, and functionality to guarantee the integrity and reliability of the final product.

Manufacturing Assembly & BOMs

Packaging and Shipping: Once the assembly is complete, the finished units are carefully packaged to protect them during transportation. Proper labeling and documentation are also prepared for tracking and logistics purposes.

The assembly process within a pressings company like TWP Manufacturing combines specialised manufacturing techniques with meticulous attention to detail. By following the BOM and adhering to quality control procedures, the pressings company can ensure that each component is correctly assembled to produce a finished unit that meets the desired specifications and customer requirements. Think we can help? Then why not call us today and support UK Manufacturing!

Want to find out more?

If you are working on a project which includes the design, manufacture and assembly processes, then we are your perfect match. Click on the button below to start your manufacturing journey with TWP Manufacturing.